Soda/Multi Media Blaster 1650/2500

Blast Boss’ Multi-Media Blaster (MMB) is a versatile, turn-key system that can utilize a wide range of blast media including: sodium bicarbonate, Super K (potassium sulfate), crushed glass, crushed corn cob, garnet and other abrasives. The Blast Boss MMB system can be used for a wide range of applications: mold remediation, fire & smoke damage restoration, general maintenance, cleaning, de-greasing, coating removal and surface preparation.

Blast Boss’ MMB is lightweight and portable yet strong and durable. The MMB has been tested and proven by Blast Boss professionals to ensure trouble-free, quality results. Knowledgeable technical support is available and with our unparalleled field experience we can help you manage even the most difficult projects. Call Blast Boss today to get the best media blaster on the market.

Blast Boss offers a complete blasting package for people that are starting out. This package includes the ST1650 or ST2500 blast unit, #4 or #5 nozzle, 50ft of blast hose, electric deadman switch (12volt), water separators, air pressure regulators, 50 ft air supply hoses, operators manual, a 250 cfm after cooler for the compressor, and an additional 250 cfm water separator for the compressor.

For a soda blasting pot to run efficiently it needs to have cool, dry air. This is why we include an after cooler and an additional water separator in our MMB Blasting Package. When an air compressor creates the air to be used, the air will become heated. This air then needs to be cooled to a more desirable temperature for the soda blasting pot. This is the reason for the after cooler we include in our blasting package. It is a simple and reliable after cooler with a 12volt fan that can be connected to the compressor battery. Unfortunately, when you cool compressed air it will generate moisture causing the need for a water separator. The water separators included with the blasting pot normally remove most of the moisture. It has been noted that some compressors can produce more moisture than the water separators on the pot can handle. Also, some customers like ourselves work in geographical areas where humidity can reach 100% in the summer. To correct this, we include an additional water separator in our blasting package. This water separator can be mounted on the after cooler. Since we have starting using this water separator, we and our customers have experienced no moisture problems. In fact, we hardly ever see any moisture making it to the water separators on the blasting pot.

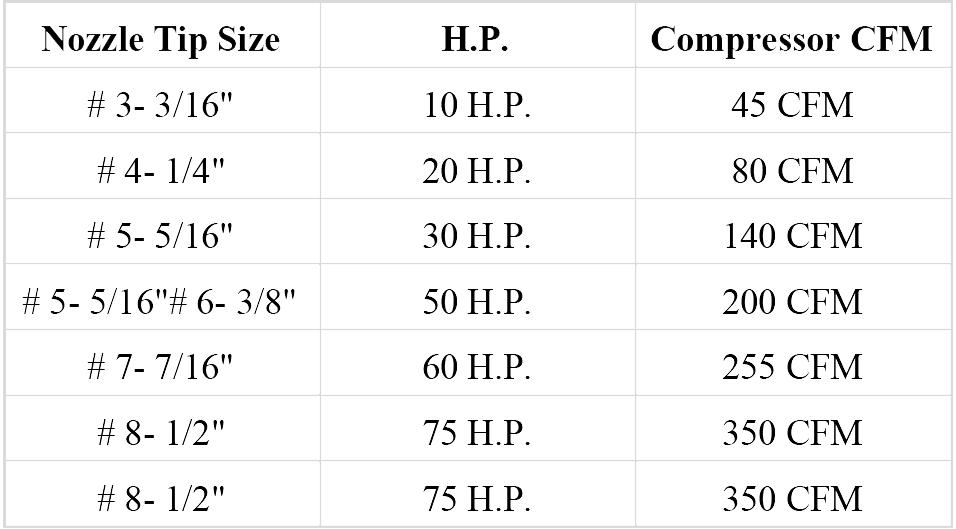

The CFM capability of your compressor and the type of blasting job you are doing will determine the size selection of the blast nozzle. If you have a large blasting job like a bulldozer, pipe lines, or a three storey building you may want a larger blast nozzle. If you are doing smaller jobs like an iron gate, fireplace, or a car you may want a smaller blast nozzle. Keep in mind that your nozzle size can not exceed the CFM capabilities of your compressor. After a brief consultation we can help determine the best set up for you

The following list compares the blast nozzle size to the compressor CFM requirements.

Blasting Equipment is custom powder coated and available in any color upon request. Listed below are primary colors used.

Documents will open in a new window. If you do not have Adobe Reader, you must download it to view PDF documents.

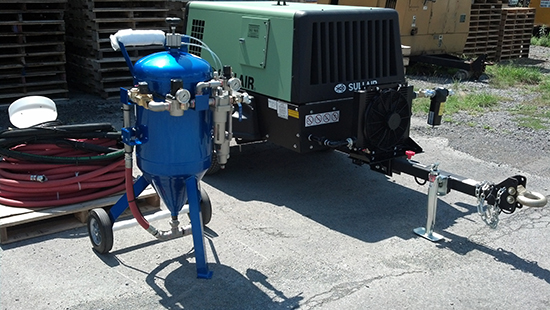

Sullaire Blast Package

The Sullaire 185 CFM compressor package is a turn-key blasting system. We have found this package to be very popular with our customers, due to the compact size, fuel efficiency and low maintenance costs. This is an smart alternative to our trailer systems, while sticking to a tight budget. This system offers the same performance as our trailer mounted systems, without the additional cost.

Everything you need to start media blasting:

• ST1650 or ST2500 multi media blast unit

• Sullaire 185 CFM compressor

• Fuel-efficient, quiet & dependable

• 5 year/5000 hour compressor power train warranty

• 250 CFM aftercooler hard mounted to compressor tongue

• 250 CFM water separator

• 50 ft. air hose

• 50 ft. blast hose

• 12 volt electric deadman switch

• #4 or #5 tungsten carbide blast nozzle

• Powder coated compressor tongue

Mobile Aftercooler Sysytem

Why do I need a Mobile After-cooler System? That’s a great question! If you have noticed too much water coming from your compressor, you need a system! Whether they are running, air hammers, jack hammers,or blasting equipment, everything runs better with cool dry air. Have you noticed that air compressors that are 375, 750 or 900 CFM have them built right in? We noticed, and built a system for compressors 250 CFM and less.

How do we know our systems work? Every blasting system we sell has one of our mobile after-cooler systems included.. We run baking soda through our blasters, the most water sensitive media for blasting. Our equipment always runs dry, whether in Canada in the winter, or Florida in the summer. Blast Boss’ customers have been counting on our mobile after-cooler systems for years, and now your can too. We understand there are many applications in the field, and we offer solutions for many of them.

This system is designed for the job site where up to two outlets are required. Can be used on the ground, or attached to the compressor for movement around the job site. The integral safety cage, is designed to protect the cooler in case of abuse. Includes our 250 CFM 12 volt after-cooler, and is custom powder coated for a long service life.universal after-cooler caddy.

This system is designed for use when multiple tools are being used. We designed this system with (3) 1″ ball valves and (2) standard air fittings. The surge tank also allows multiple tools to be cycled on and off, without leaving any tools starving for air. This is the same system we use on our blast rigs, when multiple blast pots are in use. This system can be custom configured for different applications.

Blasting Trailers

We have been working on the new Blast Boss rig for some time now, and it’s finally here. When we started building trailers over ten years ago, we were supplying our own crews with equipment. They beat it up, told us what they wanted and our first generation trailer was developed.

The next generation trailer is here and we are again proud to offer something know one else is building.

1. Choice of compressor size 185 CFM, High Pressure 200 CFM, 375 CFM

2. Upgraded heavy duty torsion axles

3. Upgraded heavy duty tires

4. Upgraded heavy duty frames

5. 2 5/16 Bull Dog Coupler

6. 2.5 CU/FT blaster

7. Tool Boxes for storing and securing equipment, any size available

8. Heavy Duty Boxed aluminum frame..reduces trailer weight by 20%

Trailer pictured is 18 ft with 8 ft stand up box, fully enclosed V-Nose, fully secured and lockable. 1000 lb folding Ramp, with man door and step. E-trac on side walls for securing equipment, inside lights, 4 inside tie downs. 5200 lb axles, 2 5/16 bulldog coupler, rear jacks for stabilizing trailer on job sites. 200 CFM high pressure air compressor, after cooling package, 2.5 CU/FT blaster with all hoses and shutoffs.